Product Description

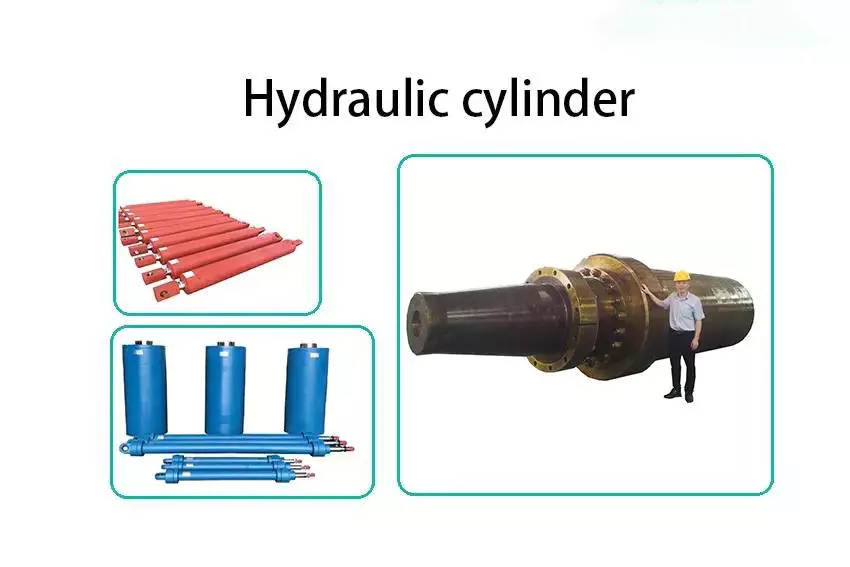

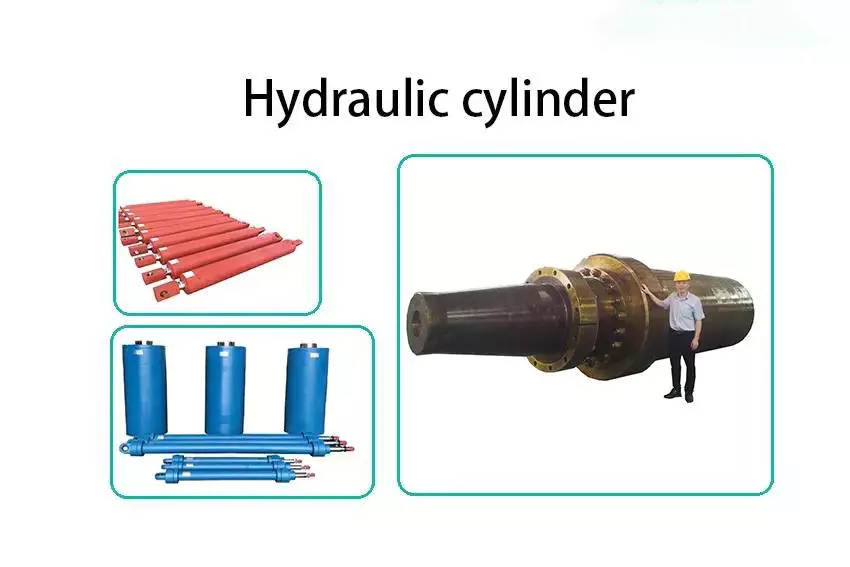

Factory Price Custom Double Acting Garbage Truck Hydraulic Cylinders Telescopic Cylinders

Hydraulic Cylinders : Hydraulic Cylinder Assemble with imported seals kits of NOK, Hallite and other brands to bring the better seal slick and the stronger persistence.

Process with the advanced technology by CNC machine tools, automatic plating and painting equipments to ensure all the parts to have the lower surface roughness and the higher performance level.

Own advanced special buffer device with independent intellectual property rights which can effectively absorb the shock to protect the cylinder work smoothly and reliable in performance.

Specifications

| Item | Specifications |

| Product Name: | Factory Price Custom Double Acting Garbage Truck Hydraulic Cylinders Telescopic Cylinders |

| CE, ISO9001 | |

| Production Capacity: | 200,000 pcs per year |

| Sample Time: | 7-10 days |

| Brand | NOLANSE or customer’s logo |

| Service | OEM & ODM |

| Piston Rod | Chrome or nickel plated,ground & polished piston rod |

| Seal Type | Parker,NOK, BUSAK SHAMBAN or as customer’s requirement |

| Tube | High tensile cold drawn tube, precision honed for extended seal life |

| Delivery Time | Based on order quantity. normally 15-30 days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer & Exporter |

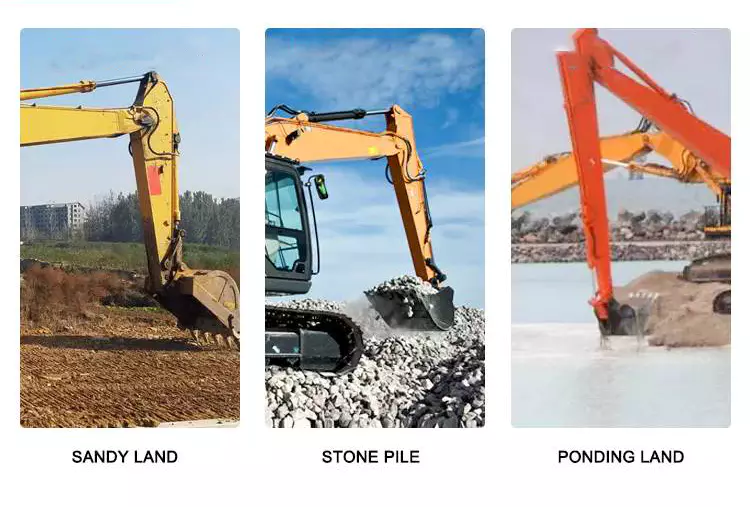

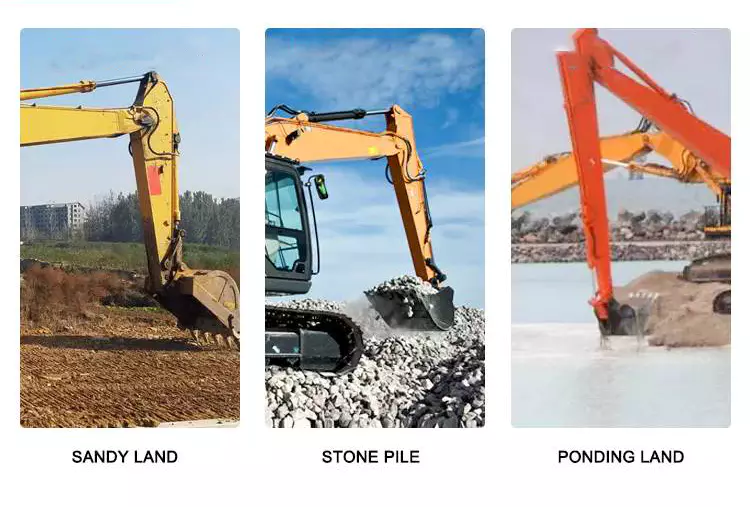

Application

Hydraulic Cylinder Product Application

Nolanse’s quality custom products are produced for OEM applications in a wide variety of worldwide industries, including manufacturing engineering machinery, loaders hydraulic cylinders, vehicle cylinders, construction, forestry, waste management, mining, material handling, industrial applications, agriculture, manufacturing, transportation, marine applications and oil field equipment. Our success has been built on the engineering expertise and manufacturing capabilities we offer to meet the very specific demands of our industry clients.

Why Choose Us

1. Product Research & Development

CZPT builds quality products that are developed with use in mind. We specialize in working with every customer to share ideas and gather critical information regarding hydraulic cylinder fit and performance requirements for your specific application. This is accomplished by establishing a very close technical rapport with each customer and their engineering, purchasing and R&D departments – the experts in your organization who know best what functionality, quality, size and cylinders characteristics are critical to your equipment. If our standard lines don’t suit your application, CZPT has extensive experience in custom hydraulic cylinder designs. We strive to develop dynamic, innovative and dependable hydraulic and machining solutions that exceed your expectations.

2. Hydraulic Cylinder Production

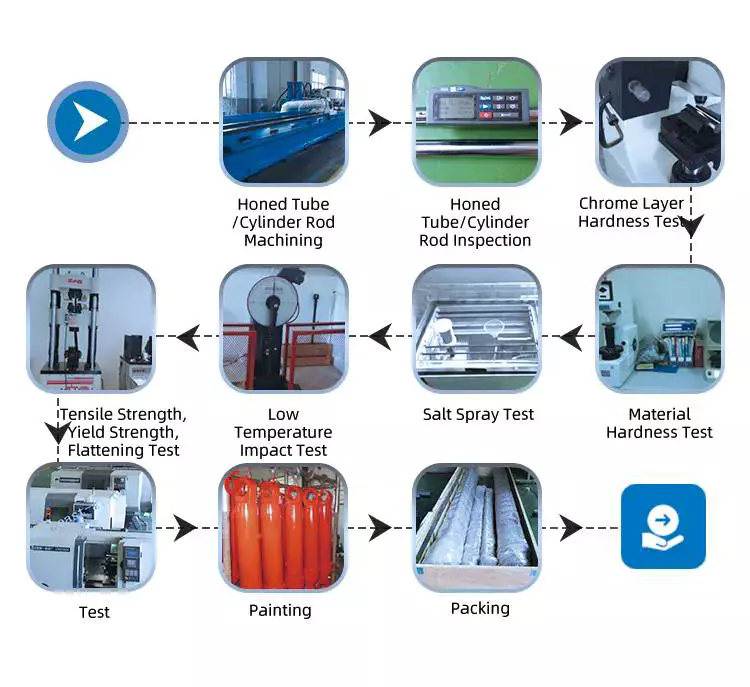

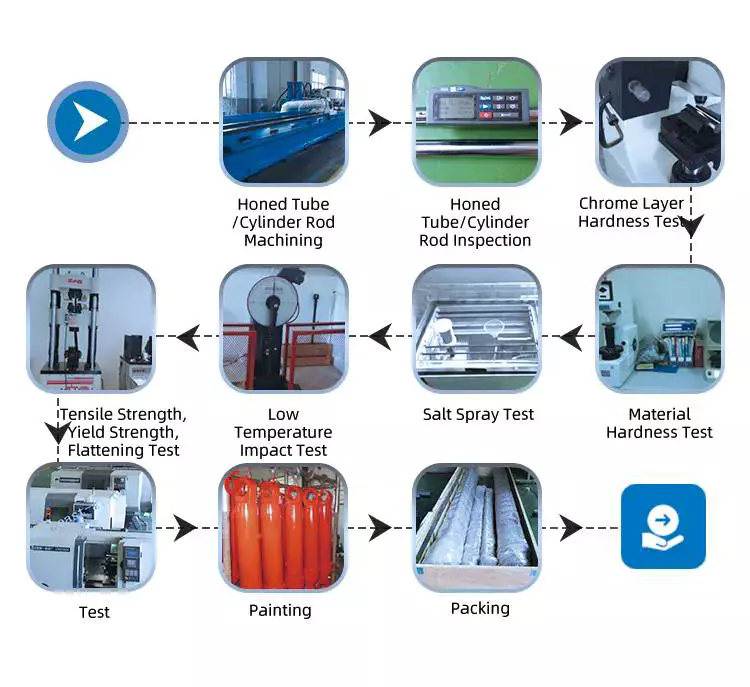

We have the advanced CNC machine tools, a horizontal machining center, a welding robot, parts cleaning agent, automatic assembly lines, automatic painting equipment etc. to hydraulic cylinder ensure a 360-degree quality control of the production process.

3. Hydraulic Cylinder Product Testing

We check all of the products, using fully equipped facilities and advanced instruments, regarding the performance, structure, size tolerance, roughness, hardness, pressure and sealing to ensure the hydraulic cylinder quality meets the requirements of our different customers.

4.Hydraulic Cylinder Product Certifications

Nolanse is ISO 9001 registered for the design and manufacture of hydraulic cylinders and precision machining.

5. Professional Hydraulic Cylinder Team

NOLANSE professional hydraulic cylinder team deeply understands the requirements and the technological advancement hydraulic ram. NOLANSE has been specialized in custom hydraulic cylinder development, manufacturing, sales, sample verification, order processing and product delivery, etc. NOLANSE is always working hard with passion to put our efforts to hydraulic cylinder technology and application.

Company Information

As a leader in hydraulic cylinder Design, Manufacturing and Custom Machining for over 36 years, NOLANSE has its own over 220 employees and over 55,000 square meters manufacturing factories. We have professional departments including hydraulic cylinder design, sales, production, quality control department, etc.

NOLANSE hydraulic cylinder products mainly include manufacturing engineering machinery,loaders hydraulic cylinders,vehicle cylinders,hydraulic systems and air controlling systems.It can also manufacture large-scale,non-standard and different stypes of cylinders, etc. All our hydraulic cylinder are manufactured from high quality raw materials with strict professional process and quality assurance. We had been worked hard and invested more to become the leader in hydraulic cylinder industry. Our partners are those famous hydraulic cylinder brands from America, Canada, Australia, Germany, England and other European Countries. Product quality, shorter delivery time and customer satisfaction are our long term commitment to our worldwide customers. Hope to be your partner.

Nolanse’s name has become synonymous with quality, on time delivery and exceptional service.

Join the growing number of partner relationship companies that trust and rely on the CZPT name.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 299/Piece

1 Piece(Min.Order) | Order Sample Customize according to customer′s requirement

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Hydraulic Cylinders

Basically, hydraulic cylinders are mechanical actuators that are used for giving unidirectional force. These cylinders are used for many different applications, such as manufacturing machinery, elevators, construction equipment, and more.

Piston seals

Choosing the right piston seals for hydraulic cylinders can help ensure proper operation of the system. The seals help to prevent leakage of fluid. They also protect the internal parts of the cylinder from damage.

The seals can also help to maintain the pressure of the fluid inside the cylinder. There are many different seals that are available. Choosing the right one for your system requires a consideration of several factors. The type of system used will depend on the type of application, as well as the conditions and duty levels of the machine.

Seals can be either single-acting or double-acting. Single-acting seals move the piston in a single direction. Double-acting seals have the same sealing functions in both directions.

The seals can be made from different materials. Standard piston seals are made from polyurethane. PTFE seals are also a popular choice. They are less prone to friction and can handle higher temperatures. The durability of the seals depends on the quality of material used.

Seals also come in different designs. They can be made from a variety of materials, including plastic. Plastic materials have a higher temperature resistance, but are less flexible than rubber. They also have less tolerance for tearing. The material used for the seal must meet the chemical and mechanical property requirements.

The material used to make the piston seals is critical to its performance. PTFE seals are the most popular choice. They are highly resistant to abrasion, provide better elasticity, and maintain constant pressure for longer periods of time. They also have a low coefficient of friction. They are highly recommended for all hydraulic cylinders.

Seals can also be used to prevent fluid from flowing around the piston. Wiper seals, for example, are sometimes referred to as dust seals. They prevent contaminants from entering the cylinder.

Welded rod cylinders

Whether you are looking for a hydraulic cylinder to use on a vehicle or a piece of industrial equipment, there are a number of different options available. Some of these options include welded rod hydraulic cylinders, which are designed for use in harsh environments. Welded rod cylinders can also be custom-engineered to meet your specific needs.

These cylinders are a good option for a wide range of applications. They have a durable design that is ideal for industrial use, and they are usually easy to maintain. In addition, welded rod cylinders can be used in mobile equipment, as well.

When looking at hydraulic cylinders, it is important to know what type you are looking for. There are two main types: tie rod cylinders and welded rod cylinders. Each type has its own advantages and disadvantages.

Tie rod cylinders are a good option for easy maintenance, but they are not as durable as welded rod cylinders. They also require more installation space than welded rod cylinders. This is especially true if you are working with mobile equipment.

Welded rod hydraulic cylinders are more durable, and they are designed to withstand the stresses of extreme environments. They also have a higher duty cycle than tie rod cylinders, which makes them ideal for mobile equipment. In addition, they have longer internal bearing lengths, which helps to ensure a longer operating life.

Tie rod cylinders are generally cheaper to manufacture. They are NFPA-approved, and they can be easily disassembled to allow for service. They also have a higher installation space, but they are easier to maintain. They also work well in low pressure applications, and are suitable for industrial manufacturing applications with low pressure requirements.

Double-acting cylinders

Unlike single acting hydraulic cylinders, double acting hydraulic cylinders can exert pressure on both sides of the piston. This allows them to perform more complex actions with less energy. This is especially useful for applications that require precise and controlled retraction.

Double acting hydraulic cylinders are also used in a variety of industrial and medical applications. They are especially useful in robotics, heavy-duty equipment, and mobile equipment. They can be used in the lift and press of merchandise from conveyor belts, as well as in excavators. They are also used in tow trucks.

They are more expensive than single acting hydraulic cylinders, but their performance is also greater. They are more rugged and work faster. They are also more efficient and offer more design options. They are also more likely to be ISO compliant.

Double acting hydraulic cylinders are typically used to control steering in excavators. They are also used to control the boom of a TLB. They are also used in mobile applications, such as a dump trailer hoist.

They are manufactured into a single acting or double acting model, depending on the application. They are also available in a number of different designs, including hollow plunger models.

They can also be fitted with sensors to improve stroke control. These sensors provide feedback to a controller and allow the piston to change its stroke in response to various conditions. This is especially useful in heavy mobile equipment, such as tow trucks.

They are also referred to as position sensing cylinders. They can detect the position of the piston and provide feedback to a controller, which can then adjust the stroke in order to match the precise function of the machine.

Surfaces of hydraulic cylinders are given special treatment

Several different surface treatments are used to improve the performance of hydraulic cylinders. Some of these treatments are performed externally while others are carried out internally.

Several of these treatments include the use of a coating. The purpose of this coating is to reduce wear and corrosion. In addition, manufacturers have developed alternative coatings to increase service life.

The most important mechanical properties include hardness, yield strength, and tensile strength. The coating will improve these properties and protect the cylinder from physical and chemical attacks.

The most significant benefit of using a coating is that it increases the ability to reduce wear. The same coating can also improve the frictional properties of a cylinder.

The use of a coating is also important for the prevention of leakage. The seal should be inspected periodically. Several types of coatings are used in the field of cylinders, including hard chrome plating, polymers, and iron alloys.

A single clevis with a spherical ball bearing is the ideal connection for a hydraulic cylinder. This connection allows a misalignment of the actuator. Ideally, the clevis and ball bearing will not transmit bending moments. In order to avoid this, mechanical stops should be used to limit retraction.

The clearance between a friction pair plays a significant role in hydraulic cylinder assembly. For optimum friction properties, the clearance should be no less than 25 mm. However, too much clearance can increase internal leakage.

To determine the appropriate friction coefficient, the equivalent flow method is used. In this method, the friction coefficient is equal to the ratio of the friction force to the normal force. The effect of roughness on frictional properties is also studied. The roughness is measured during the preparation of the substrate.

Common uses of hydraulic cylinders

Various industries use Hydraulic Cylinders in their processes. These devices are used in heavy machinery such as excavators, construction machines and agricultural equipment. They are also used in various transportation devices and equipment. They are also found in feeding devices, plastic forming machines and gate controls.

Hydraulic cylinders can be single or double acting. They can also be telescopic or plunger style cylinders. They are made up of a piston, rod end, base and head. Some common differences include the cylinder’s wall thickness, material used, operating pressure and its method of connecting end caps.

Hydraulic cylinders are based on the principle of Pascal. In the mid 1800s, they were used for lifting on cranes. They were also used for controlling cannons in the military. They were also used in construction technology and mining.

The fluid inside the cylinder can be non-corrosive or corrosive. Generally, oil was used because it was resistant to evaporation. It also stayed cooler at high pressures. Hydraulic cylinders use less power and are much more efficient than other forms of the same device.

Hydraulic cylinders can also be used for food packaging. They have been used to achieve precision in packaging machines. Hydraulic cylinders are used for lifting, pressing, and other processes in agriculture. They are also used in spraying, seeders, conveyor belt systems and more.

Hydraulic cylinders are also used for material handling, transportation, construction, and industrial applications. They are used in various heavy machinery such as tractors, excavators, and skid steers. They are also used in forestry and manufacturing equipment.

Depending on the application, there are different types of hydraulic cylinders. These include single acting cylinders, double acting cylinders, telescopic cylinders, plunger cylinders, and welded body cylinders.

editor by Dream 2024-05-02

China best Arm/Boom/Stick RAM PC1250-8 CZPT Excavator Hydraulic Cylinder for Sale wholesaler

Product Description

Komatsu PC1250-8 Excavator Arm/Boom/Stick Ram Cylinder

| Material | Komatsu PC1250-8 Excavator Arm/Boom/Stick RAM Hydraulic Cylinder |

| Type | double acting hydraulic cylinder |

| MOQ | 1piece |

| Paint color | Black,Yellow,Blue,Brown,Customizable |

Roca specializes in manufacturing hydraulic cylinder for many well-known construction machinery manufacturers such as Hitachi, Cat, Parker, Komatsu, Volvo, Doosan, etc. (Top quality aftermarket Spare Parts)

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

ROCA team takes all your concerns into consideration to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Choosing Hydraulic Cylinders

Typically, hydraulic cylinders are used in applications such as manufacturing machinery, construction equipment, and civil engineering. They are also used in elevators and other applications where the use of a mechanical actuator is necessary.

Piston seals

Choosing the correct piston seals for hydraulic cylinders can help to ensure the proper operation of the cylinder. Seals are designed to keep fluids and contaminants from flowing across the cylinder. However, external factors can affect their performance. In order to choose the right seals, it’s important to understand the different types.

There are two basic piston seal types. One is a double acting seal that maintains pressure on both sides of the piston. The other type is a single acting seal that maintains pressure on only one side of the piston.

Double acting piston seals are typically made of a slide ring. They maintain the pressure in a hydraulic cylinder and allow the ram to move in a controlled direction. The slide ring is normally made of a plastic material. However, it is important to select a material that is suitable for the fluid pressure that is expected.

Single acting cylinder seals are designed for cylinders where one side of the piston is under high pressure and the other side is under low pressure. These seals are usually designed to provide the best sealing characteristics.

In addition to the seal, it is important to select the right guide. A guide is a metal strip or ring that keeps the piston and the piston rod radially centered in the cylinder assembly. This guide also keeps metal-to-metal contact between the two components.

For high-pressure applications, it is recommended to use piston seals made from PTFE. These seals can withstand temperatures up to 800 degrees Celsius. They have less friction than rubber seals and are also resistant to abrasion. However, they are not as durable as thermoplastic elastomers.

The seals are designed to maintain a constant pressure for a longer period of time than other materials. In addition, they are resistant to tearing, and they stand up to high use.

Coatings for hydraulic cylinders

Various coatings for hydraulic cylinders are available in the market. The main purpose of these coatings is to provide protection against physical and chemical attacks. These coatings are usually applied externally or internally.

Plasma spray is one of the most common surface modification methods. It combines flame and arc spray to deposit metallic or ceramic materials onto the surface. This process improves the operating characteristics of actuators. It is also useful in repairing damaged surfaces.

Another popular surface treatment is liquid nitrating. It produces a hard iron nitride layer that has excellent surface hardness. It also provides a good surface resistance. It can be used as a thermal barrier coating on stationary gas turbine blades.

Hard chrome over nickel coating is also a common type of coating for hydraulic cylinders. It provides good corrosion resistance and abrasion resistance. It is plated onto the surface and then polished.

Another popular surface modification method is thermal spray. It uses engineered materials to deposit metallic or ceramic materials onto the surface. It is a cost effective solution to surface enhancement. It also eliminates the need for costly replacement parts.

In addition, WC-CoCr coatings provide good wear resistance and corrosion resistance. These coatings are particularly useful for parts that are subjected to harsh working conditions.

Ceramic plating is mostly used in the aerospace and military industries. It also reduces friction and provides heat shielding. It can also be used as an alternative to hard chrome coatings.

The most important mechanical properties are the hardness, yield strength and the tensile strength. The material selection should be based on the shape and dimensions of the object being produced. This article will discuss the most commonly used materials and give an overview of the most effective surface modification methods.

Double-acting cylinders

Basically, hydraulic cylinders are used in a variety of applications, including engineering, industrial furnaces, and lift shafts. They are also used in subsea environments, shipbuilding, and oil & gas.

A double-acting hydraulic cylinder is a type of hydraulic cylinder that combines the best features of a single-acting cylinder with some additional advantages. These benefits include higher force, greater flexibility, and more control. Double-acting hydraulic cylinders are generally used in high-powered applications, such as lift shafts, excavation equipment, and robotics. They are also used in mobile applications, such as earthmoving equipment.

The main difference between single acting and double-acting hydraulic cylinders is the way the piston is moved up and down the cylinder bore. Double-acting cylinders use hydraulic fluid to apply pressure on both sides of the piston rod.

Another advantage of double-acting hydraulic cylinders is their ability to extend and retract without the need for an external force. In contrast, single acting cylinders require an external source to move the piston.

Double-acting hydraulic cylinders are more expensive than single-acting cylinders. This is because they have a larger housing and require more dedicated maintenance. They are also more costly to buy.

However, they are also more accurate and efficient. Double-acting cylinders work faster and can be used in virtually any application. They are also better for industrial tasks, such as lifting merchandise off conveyor belts. They can also work in an angle, and they are suitable for mobile applications.

In addition to their performance, double-acting hydraulic cylinders are more likely to be ISO compliant than single-acting cylinders. They also offer more design options.

Depending on the needs of the application, a double-acting hydraulic cylinder may be more expensive than a single-acting cylinder. This is because the piston seal must be designed to work with the fluid. The seal material is generally rubber or a rubber/fabric composite.

Stainless steel cylinders

Stainless steel hydraulic cylinders are used in numerous industries. They are known for their durability and rust resistance. They are used in industrial hydraulics applications, as well as in the food and beverage processing industry. They also help processing facilities meet industry standards.

Stainless steel hydraulic cylinders are made of a stainless steel alloy that contains at least 10% chromium. The chromium oxide forms a thin layer on the steel’s surface, contributing to its corrosion resistance. The alloy also develops a non-porous surface that prevents bacteria from lingering. It also contributes to the steel’s ability to self-repair.

Stainless steel hydraulic cylinders are widely used in the food and beverage processing industry. They are particularly useful for moving heavy loads. They can withstand frequent cleaning operations. They also provide excellent strength. They are commonly used in chocolate molding machines and cold press juicers.

Stainless steel hydraulic cylinders are available from Maverick Machine & Hydraulics. They can be customized to meet your specifications. They can be manufactured with a satin finish or a streamlined design. They can also be custom colored. The manufacturer will provide full service and a competitive price.

Hydraulic cylinders are used to push, pull, or push-pull heavy loads. They are designed to withstand extreme temperatures. They are also available in single and double-acting configurations. They are commonly used in pharmaceutical, food, chemical, and marine applications. They are also used on coastal power generation plants and pipeline risers. They are also used in water treatment plants. They can also be used on oil platforms.

There are two types of hydraulic cylinders, which are single-acting and double-acting. The single-acting type has a single fluid chamber, while the double-acting model has more fluid in the pressurized chamber. The single-acting cylinder is more affordable to maintain and easier to control.

Pivot rod style cylinders

Choosing hydraulic cylinders requires a great deal of attention to detail. You will need to consider the following factors: cylinder length, rod size, rod seals, bearing loads, and the type of cylinder you need.

Hydraulic cylinders are used in a variety of applications, such as lifting and lowering buckets, as well as jack knifing and metal sheet shearing machines. They are also used in hydraulic bending machines and earth-moving equipment.

The main sleeve or barrel of a hydraulic cylinder extends to its maximum stroke. It can be either single or double acting, and can be either stationary or pivoting. This allows a cylinder to move a load in a straight line or a circular path.

Cylinders have a variety of mounting styles, including clevises, flanges, and side mounts. Flange mounts are generally used in force-transfer applications where the cylinder must be parallel with the load. Flanges come in several shapes and sizes, including a square flange, a rectangular head, or a cap. Aside from transferring load, they also absorb force along the cylinder centerline.

Cylinders have a variety and range of seals, which are used to prevent hydraulic fluid leakage past the interface. These seals are made of various materials, including metal and elastomeric seals. The materials used for these seals depend on the application. These seals also vary in terms of pressure, temperature, and temperature changes.

Clevises and flanges are two common mounting styles for hydraulic cylinders. They are used to provide structural support for bolts. These mounts also work to absorb force along the cylinder’s centerline. These mounting styles have less rod bearing loads than other types, but they must be properly aligned with the load.

editor by Dream 2024-04-30

China high quality Hydraulic Telescopic Wheel Loader1500kg 2000kg 2500kg 3000kg CZPT Cylinder with Agricultural/Industrial/Forestry New Wheel Loader Various Construction Sites supplier

Product Description

Hydraulic Telescopic Wheel Loader1500kg 2000kg 2500kg 3000kg CHINAMFG Cylinder with Agricultural/Industrial/Forestry New Wheel Loader wVarious Construction Sites

Factory Direct Sales, Support Wholesale Price Purchases!

| SPECIFICATION | ZHS2500T | ZHS3000T | |

| Specification | overall weight(kg) | 7000kg | 8000kg |

| L*W*H(mm) | 7350*2000*2850mm | 8750*2100*2900mm | |

| Rated bucket capacity(m3) | 1.0cbm | 1.2cbm | |

| rated load(kg) | 2500kg | 3000kg | |

| Max-dump height (mm) | 4800mm – 6800mm | 4800mm – 9000mm | |

| Max-Lifting height (mm) | 7000mm – 9000mm | 7000mm – 11000mm | |

| Engine | Brand and model | Yunnei | Yuchai |

| Type | Four Stroke Water Cooling | Four Stroke Water Cooling | |

| Rated power(kw) | 76kw | 85kw | |

| Rated speed(r/min) | 2400r/min | 2400r/min | |

| Transmission system | Working pressure(Mpa) | 16Mpa | 16Mpa |

| Gearbox type | hydraulic torque converter | hydraulic torque converter | |

| Steering system | Max. turning angle | 35°±1 | 35°±1 |

| Tire | Standard tire | 16/70-20 | 16/70-24 |

Q: Are you a manufacturer?

A: Yes, we are a manufacturer, we have our own factory. And we are the top supplier in China. We promise that we are exactly the supplier you have been looking for. We welcome you to visit our factory to check our production lines and know more about our capacity, quality.

Q: Do you have quality control system?

A: Yes, we have ISO, CE and our own quality control team. And we will do a lot of different tests to make sure it works fine

Q: Can you arrange the shipment for us?

A: Yes, we have appointed shipping and rail freight forwarders with decades of experience, and we can get the best prices through designated vessels and professional services.

Q: How long is your delivery time?

A: Generally it is 7-14 days, we have the Machinery in our stock.

Q: Can you reduce the price?

A: Yes, we have some discount for new customers, you will get the best quality and price from me.

Q: How do you keep long-term business and good relationship ?

A: 1.We keep supplying good quality products and competitive prices to ensure our customers’ benefit.

2. We think highly of every single customers of us and value the relationship, we take it not only as business partner, but also as true friends. Will keep the good services and put customers’ benefit as high priority.

3. My job is to help customers buy the highest quality machinery at the best price.

4. Our goal is to help customers save money and help customers make money.

We Understand You! We Care About What You think!

ZHS is always With You ♥♥♥♥♥♥

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours Online After-Sales Service |

|---|---|

| Warranty: | 1year |

| Certification: | TUV, ISO, RoHS, CE |

| Condition: | New |

| Rated Load: | 1-3t |

| Transmission: | Hydraulic |

| Customization: |

Available

|

|

|---|

What advancements in hydraulic cylinder technology have improved sealing and reliability?

Advancements in hydraulic cylinder technology have continuously contributed to improving sealing and reliability in hydraulic systems. These advancements aim to address common challenges such as leakage, wear, and failure of seals, ensuring optimal performance and longevity. Here are several key advancements that have significantly improved sealing and reliability in hydraulic cylinders:

1. High-Performance Sealing Materials:

– The development of advanced sealing materials has greatly improved the sealing capabilities of hydraulic cylinders. Traditional sealing materials like rubber have been replaced or enhanced with high-performance materials such as polyurethane, PTFE (polytetrafluoroethylene), and various composite materials. These materials offer superior resistance to wear, temperature, and chemical degradation, resulting in improved sealing performance and extended seal life.

2. Enhanced Seal Designs:

– Advancements in seal designs have focused on improving sealing efficiency and reliability. Innovative seal profiles, such as lip seals, wipers, and scrapers, have been developed to optimize fluid retention and prevent contamination. These designs provide better sealing performance, minimizing the risk of fluid leakage and maintaining system integrity. Additionally, improved seal geometries and manufacturing techniques ensure tighter tolerances, reducing the potential for seal failure due to misalignment or extrusion.

3. Integrated Seal and Bearing Systems:

– Hydraulic cylinders now incorporate integrated seal and bearing systems, where the sealing elements also serve as bearing surfaces. This design approach reduces the number of components and potential failure points, improving overall reliability. By integrating seals and bearings, the risk of seal damage or displacement due to excessive loads or misalignment is minimized, resulting in enhanced sealing performance and increased reliability.

4. Advanced Coatings and Surface Treatments:

– The application of advanced coatings and surface treatments to hydraulic cylinder components has significantly improved sealing and reliability. Coatings such as chrome plating or ceramic coatings enhance surface hardness, wear resistance, and corrosion resistance. These surface treatments provide a smoother and more durable surface for seals to operate against, reducing friction and improving sealing performance. Moreover, specialized coatings can also provide self-lubricating properties, reducing the need for additional lubrication and enhancing reliability.

5. Sealing System Monitoring and Diagnostic Technologies:

– The integration of monitoring and diagnostic technologies in hydraulic systems has revolutionized seal performance and reliability. Sensors and monitoring systems can detect and alert operators to potential seal failures or leaks before they escalate. Real-time monitoring of pressure, temperature, and seal performance parameters allows for proactive maintenance and early intervention, preventing costly downtime and ensuring optimal sealing and reliability.

6. Computational Modeling and Simulation:

– Computational modeling and simulation techniques have played a significant role in advancing hydraulic cylinder sealing and reliability. These tools enable engineers to analyze and optimize seal designs, fluid flow dynamics, and contact stresses. By simulating various operating conditions, potential issues such as seal extrusion, wear, or leakage can be identified and mitigated early in the design phase, resulting in improved sealing performance and enhanced reliability.

7. Systematic Maintenance Practices:

– Advances in hydraulic cylinder technology have also emphasized the importance of systematic maintenance practices to ensure sealing and overall system reliability. Regular inspection, lubrication, and replacement of seals, as well as routine system flushing and filtration, help prevent premature seal failure and optimize sealing performance. Implementing preventive maintenance schedules and adhering to recommended service intervals contribute to extended seal life and enhanced reliability.

In summary, advancements in hydraulic cylinder technology have led to significant improvements in sealing and reliability. High-performance sealing materials, enhanced seal designs, integrated seal and bearing systems, advanced coatings and surface treatments, sealing system monitoring and diagnostics, computational modeling and simulation, and systematic maintenance practices have all played key roles in achieving optimal sealing performance and increased reliability. These advancements have resulted in more efficient and dependable hydraulic systems, minimizing leakage, wear, and failure of seals, and ultimately improving the overall performance and longevity of hydraulic cylinders in diverse applications.

Can you provide real-world examples of machinery that heavily rely on hydraulic cylinders?

Hydraulic cylinders are widely used in various industries and applications due to their ability to provide powerful and precise linear motion. They play a crucial role in enabling the operation of heavy machinery that requires controlled force and movement. Here are some real-world examples of machinery that heavily rely on hydraulic cylinders:

1. Construction Equipment:

– Hydraulic cylinders are extensively used in construction machinery, such as excavators, bulldozers, loaders, and cranes. These machines rely on hydraulic cylinders to perform tasks like lifting heavy loads, extending and retracting booms, tilting buckets, and controlling the movement of various components. Hydraulic cylinders provide the power and precision required to handle the demanding conditions and heavy loads encountered in construction projects.

2. Agricultural Machinery:

– Many agricultural machines, including tractors, combine harvesters, and sprayers, utilize hydraulic cylinders for critical operations. Hydraulic cylinders are used to control the movement of attachments, such as front loaders, backhoes, and plows. They enable functions like lifting and lowering implements, adjusting cutting heights, and controlling the positioning of harvesting equipment. Hydraulic cylinders enhance efficiency and productivity in agricultural operations.

3. Material Handling Equipment:

– Hydraulic cylinders are integral components of material handling equipment, such as forklifts, pallet jacks, and cranes. These machines rely on hydraulic cylinders to lift and lower loads, tilt platforms or forks, and control the movement of lifting mechanisms. Hydraulic cylinders provide the necessary strength and precision to handle heavy loads and ensure safe and efficient material handling operations.

4. Industrial Machinery:

– Various industrial machinery and equipment heavily rely on hydraulic cylinders for critical functions. Examples include hydraulic presses, injection molding machines, metal-forming machines, and hydraulic-powered robots. Hydraulic cylinders enable precise control of force and movement in these applications, allowing for accurate shaping, pressing, and assembly processes.

5. Mining Equipment:

– Hydraulic cylinders are extensively used in mining machinery and equipment. Underground mining machines, such as continuous miners and longwall shearers, utilize hydraulic cylinders for cutting, shearing, and roof support operations. Surface mining equipment, including hydraulic shovels, draglines, and haul trucks, rely on hydraulic cylinders for tasks like bucket movement, boom extension, and vehicle suspension.

6. Automotive Industry:

– The automotive industry extensively utilizes hydraulic cylinders in various applications. Hydraulic cylinders are employed in vehicle suspension systems, power steering systems, convertible tops, and hydraulic brake systems. They enable smooth and controlled movement, precise steering, and efficient braking in automobiles.

7. Aerospace and Aviation:

– Hydraulic cylinders are utilized in aerospace and aviation applications, such as aircraft landing gear systems, wing flaps, and cargo handling equipment. Hydraulic cylinders provide the necessary force and control for extending and retracting landing gear, adjusting wing flaps, and operating cargo doors, ensuring safe and reliable aircraft operations.

8. Marine and Offshore Industry:

– Hydraulic cylinders are essential components in marine and offshore equipment, including ship cranes, winches, and hydraulic-powered anchor systems. They enable lifting, lowering, and positioning of heavy loads, as well as the control of various marine equipment.

These are just a few examples of machinery and industries that heavily rely on hydraulic cylinders. The versatility, power, and precise control offered by hydraulic cylinders make them indispensable in a wide range of applications, where controlled linear motion and force are essential.

What are the common signs of wear or leakage that indicate hydraulic cylinder issues?

Hydraulic cylinders are critical components in hydraulic systems, and wear or leakage can lead to performance issues and potential system failures. It is important to be aware of the common signs that indicate hydraulic cylinder problems. Here’s a detailed explanation of the common signs of wear or leakage that indicate hydraulic cylinder issues:

1. Fluid Leakage:

– Fluid leakage is one of the most obvious signs of hydraulic cylinder problems. If you notice hydraulic fluid leaking from the cylinder, it indicates a seal failure or damage to the cylinder. Leaking fluid may be visible around the rod, piston, or cylinder body. It is important to address fluid leakage promptly as it can lead to a loss of system efficiency, contamination of the surrounding environment, and potential damage to other system components.

2. Reduced Performance:

– Wear or internal damage to the hydraulic cylinder can result in reduced performance. You may notice a decrease in the cylinder’s force output, slower operation, or difficulty in extending or retracting the cylinder. Reduced performance can be indicative of worn seals, damaged piston or rod, internal leakage, or contamination within the cylinder. Any noticeable decrease in the cylinder’s performance should be inspected and addressed to prevent further damage or system inefficiencies.

3. Abnormal Noise or Vibrations:

– Unusual noise or vibrations during the operation of a hydraulic cylinder can indicate internal wear or damage. Excessive noise, knocking sounds, or vibrations that are not typical for the system may suggest problems such as worn bearings, misalignment, or loose internal components. These signs should be investigated to identify the source of the issue and take appropriate corrective measures.

4. Excessive Heat:

– Overheating of the hydraulic cylinder is another sign of potential issues. If the cylinder feels excessively hot to the touch during normal operation, it may indicate problems such as internal leakage, fluid contamination, or inadequate lubrication. Excessive heat can lead to accelerated wear, reduced efficiency, and overall system malfunctions. Monitoring the temperature of the hydraulic cylinder is important to detect and address potential problems.

5. External Damage:

– Physical damage to the hydraulic cylinder, such as dents, scratches, or bent rods, can contribute to wear and leakage issues. External damage can compromise the integrity of the cylinder, leading to fluid leakage, misalignment, or inefficient operation. Regular inspection of the cylinder’s external condition is essential to identify any visible signs of damage and take appropriate actions.

6. Seal Failure:

– Hydraulic cylinder seals are critical components that prevent fluid leakage and maintain system integrity. Signs of seal failure include fluid leakage, reduced performance, and increased friction during cylinder operation. Damaged or worn seals should be replaced promptly to prevent further deterioration of the cylinder’s performance and potential damage to other system components.

7. Contamination:

– Contamination within the hydraulic cylinder can cause wear, damage to seals, and overall system inefficiencies. Signs of contamination include the presence of foreign particles, debris, or sludge in the hydraulic fluid or visible damage to seals and other internal components. Regular fluid analysis and maintenance practices should be implemented to prevent contamination and address any signs of contamination promptly.

8. Irregular Seal Wear:

– Hydraulic cylinder seals can wear over time due to friction, pressure, and operating conditions. Irregular seal wear patterns, such as uneven wear or excessive wear in specific areas, may indicate misalignment or improper installation. Monitoring the condition of the seals during regular maintenance can help identify potential issues and prevent premature seal failure.

It is important to address these common signs of wear or leakage promptly to prevent further damage, ensure the optimal performance of hydraulic cylinders, and maintain the overall efficiency and reliability of the hydraulic system. Regular inspection, maintenance, and timely repairs or replacements of damaged components are key to mitigating hydraulic cylinder issues and maximizing system longevity.

editor by Dream 2024-04-30

China Best Sales Customized Hot Forging CNC Precision Single Acting Hydraulic Cylinder with Great quality

Product Description

Product Description

We provide high precision manufacturing services for CNC machining/ forging /metal fabrication…

all parts can be produced according to customer’s drawings and designs.

Forgings including: mold forging , free forging, smith forging,open die forging, hot forging, cold forging.

Forging shape:Forged gear,Forged block,Forged flange,Forged ring,Forged shaft.

Product Parameters

| Production parameters | |

| Materials | alloy steel, carbon steel, stainless steel, quenched and tempered steel, aluminum, copper |

| Heat treatment | normalizing, annealing, quenching and tempering, surface quenching, induction quenching |

| Mechanical processing | CNC turning, CNC milling, CNC boring, CNC grinding, CNC drilling |

| Gear processing | hobbing, gear milling, CNC gear milling, gear cutting, spiral gear cutting, |

| nspection | Chemical composition testing, ultrasonic testing, penetration testing, radiographic testing,Magnetic testing, tensile strength testing, impact testing, hardness testing, size testing. |

| Test | Magnetic testing, tensile strength testing, impact testing, hardness testing, size testing.Chemical composition testing, ultrasonic testing, penetration testing, radiographic testing, |

| Main markets | United States, Australia, Malaysia, Israel, United Kingdom, Russia, Canada, etc. |

| Data parameters | |

| Gear module | 8-120 |

| Maximum value for gear grinding | Module 24 |

| Shaft diameter: maximum | 2 200mm |

| Axis length: maximum | 13000 millimeters |

| Gear diameter | MAX.13 000 mm |

| Spiral gear diameter | maximum. 2200mm |

| Gear shaft length: maximum | . 5000 millimeters |

Technical process

Detailed Photos

Packaging & Shipping

Certifications

Our Advantages

Excellent service attitude, fast response speed, on-time delivery, and excellent after-sales service have been our practices since the beginning. Combined with high credit, competitive prices, close interaction with customers, and innovative working methods, we have won more and more business and excellent customer satisfaction.

Choosing us as your business partner would be the most correct choice for you.

FAQ

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes, it is. After the cooperation is reached, we will plan a perfect production solution for you. The Quality inspection team will track the production process and give regular feedback on the production progress to you. Our factory will also provide pictures and videos at any time. We can also let you see the real status of the order production through video calls.

Q: Will my drawings be safe after sending them to you?

A: Sure. We have a strict privacy policy and will protect each customer’s information. It will only be given to the person you designate with your permission.

Q: Are you a trading company or factory?

It is worth mentioning that our entire production process is controlled independently and there is no outsourced processing. This means that every step from raw material procurement, forging processing, heat treatment to finished product delivery is strictly controlled by us. Through refined management and cost control, we are able to provide customers with more competitive prices while ensuring product quality.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Hardware |

| Material: | Steel |

| Heat Treatment: | Tempering |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can hydraulic cylinders be integrated with modern telematics and remote monitoring?

Yes, hydraulic cylinders can indeed be integrated with modern telematics and remote monitoring systems. The integration of hydraulic cylinders with telematics and remote monitoring technology offers numerous benefits, including enhanced operational efficiency, improved maintenance practices, and increased overall productivity. Here’s a detailed explanation of how hydraulic cylinders can be integrated with modern telematics and remote monitoring:

1. Sensor Integration:

– Hydraulic cylinders can be equipped with various sensors to gather real-time data about their performance and operating conditions. Sensors such as pressure transducers, temperature sensors, position sensors, and load sensors can be integrated directly into the cylinder or its associated components. These sensors provide valuable information about parameters such as pressure, temperature, position, and load, enabling remote monitoring and analysis of the cylinder’s behavior.

2. Data Transmission:

– The data collected from the sensors in hydraulic cylinders can be transmitted wirelessly or through wired connections to a central monitoring system. Wireless communication technologies such as Bluetooth, Wi-Fi, or cellular networks can be employed to transmit data in real-time. Alternatively, wired connections such as Ethernet or CAN bus can be utilized for data transmission. The choice of communication method depends on the specific requirements of the application and the available infrastructure.

3. Remote Monitoring Systems:

– Remote monitoring systems receive and process the data transmitted from hydraulic cylinders. These systems can be cloud-based or hosted on local servers, depending on the implementation. Remote monitoring systems collect and analyze the data to provide insights into the cylinder’s performance, health, and usage patterns. Operators and maintenance personnel can access the monitoring system through web-based interfaces or dedicated software applications to view real-time data, receive alerts, and generate reports.

4. Condition Monitoring and Predictive Maintenance:

– Integration with telematics and remote monitoring enables condition monitoring and predictive maintenance of hydraulic cylinders. By analyzing the collected data, patterns and trends can be identified, allowing for the detection of potential issues or anomalies before they escalate into major problems. Predictive maintenance algorithms can be applied to the data to generate maintenance schedules, recommend component replacements, and optimize maintenance activities. This proactive approach helps prevent unexpected downtime, reduces maintenance costs, and maximizes the lifespan of hydraulic cylinders.

5. Performance Optimization:

– The data collected from hydraulic cylinders can also be utilized to optimize their performance. By analyzing parameters such as pressure, temperature, and load, operators can identify opportunities for improving operational efficiency. Insights gained from the remote monitoring system can guide adjustments in system settings, load management, or operational practices to optimize the performance of hydraulic cylinders and the overall hydraulic system. This optimization can result in energy savings, improved productivity, and reduced wear and tear.

6. Integration with Equipment Management Systems:

– Telematics and remote monitoring systems can be integrated with broader equipment management systems. This integration allows hydraulic cylinder data to be correlated with data from other components or related machinery, providing a comprehensive view of the overall system’s performance. This holistic approach enables operators to identify potential interdependencies, optimize system-wide performance, and make informed decisions regarding maintenance, repairs, or upgrades.

7. Enhanced Safety and Fault Diagnosis:

– Telematics and remote monitoring can contribute to enhanced safety and fault diagnosis in hydraulic systems. Real-time data from hydraulic cylinders can be used to detect abnormal conditions, such as excessive pressure or temperature, which may indicate potential safety risks. Fault diagnosis algorithms can analyze the data to identify specific issues or malfunctions, enabling prompt intervention and reducing the risk of catastrophic failures or accidents.

In summary, hydraulic cylinders can be effectively integrated with modern telematics and remote monitoring systems. This integration enables the collection of real-time data, remote monitoring of performance, condition monitoring, predictive maintenance, performance optimization, integration with equipment management systems, and enhanced safety. By harnessing the power of telematics and remote monitoring, hydraulic cylinder users can achieve improved efficiency, reduced downtime, optimized maintenance practices, and enhanced overall productivity in various applications and industries.

Customization of Hydraulic Cylinders for Marine and Offshore Applications

Yes, hydraulic cylinders can be customized for use in marine and offshore applications. These environments present unique challenges, such as exposure to corrosive saltwater, high humidity, and extreme operating conditions. Customization allows hydraulic cylinders to meet the specific requirements and withstand the harsh conditions encountered in marine and offshore settings. Let’s delve into the details of how hydraulic cylinders can be customized for marine and offshore applications:

- Corrosion Resistance: Marine and offshore environments expose hydraulic cylinders to corrosive elements, such as saltwater. To mitigate corrosion, hydraulic cylinders can be customized with materials and surface treatments that provide enhanced corrosion resistance. For example, cylinders can be constructed from stainless steel or coated with protective layers like chrome plating or specialized coatings to withstand the corrosive effects of saltwater.

- Sealing and Environmental Protection: Hydraulic cylinders for marine and offshore applications require robust sealing systems to prevent water ingress and protect internal components. Customized sealing solutions, such as high-quality seals, wipers, and gaskets, can be employed to ensure effective sealing and resistance to water, debris, and contaminants. Additionally, hydraulic cylinders can be designed with protective features like bellows or boots to shield vulnerable areas from environmental elements.

- High-Pressure and Shock Resistance: Marine and offshore operations may involve high-pressure hydraulic systems and encounters with dynamic loads or shocks. Customized hydraulic cylinders can be engineered to withstand these demanding conditions. They can be designed with reinforced construction, thicker walls, and specialized components to handle high-pressure applications and absorb shock loads, ensuring reliable performance and durability.

- Temperature and Fluid Compatibility: Marine and offshore applications can expose hydraulic cylinders to extreme temperature variations and specific fluid requirements. Customization allows the selection of materials, seals, and fluids compatible with the anticipated temperature range and the specific fluid being used. Hydraulic cylinders can be tailored to maintain optimal performance and reliability under challenging temperature conditions and with the designated fluid type.

- Mounting and Integration: Customized hydraulic cylinders can be designed to facilitate easy integration and mounting within marine and offshore machinery. Mounting options can be tailored to suit the available space and structural requirements of the equipment. Additionally, customized hydraulic cylinder designs can incorporate features for easy maintenance, accessibility, and connection to the hydraulic system, ensuring convenient installation and serviceability in marine and offshore applications.

In summary, hydraulic cylinders can be customized to meet the unique demands of marine and offshore applications. Customization enables the integration of corrosion-resistant materials, robust sealing systems, high-pressure and shock-resistant designs, temperature and fluid compatibility, as well as optimized mounting and integration features. By tailoring hydraulic cylinders to the specific requirements of marine and offshore environments, reliable performance, extended service life, and efficient operation can be achieved in these challenging operating conditions.

Can you provide real-world examples of machinery that heavily rely on hydraulic cylinders?

Hydraulic cylinders are widely used in various industries and applications due to their ability to provide powerful and precise linear motion. They play a crucial role in enabling the operation of heavy machinery that requires controlled force and movement. Here are some real-world examples of machinery that heavily rely on hydraulic cylinders:

1. Construction Equipment:

– Hydraulic cylinders are extensively used in construction machinery, such as excavators, bulldozers, loaders, and cranes. These machines rely on hydraulic cylinders to perform tasks like lifting heavy loads, extending and retracting booms, tilting buckets, and controlling the movement of various components. Hydraulic cylinders provide the power and precision required to handle the demanding conditions and heavy loads encountered in construction projects.

2. Agricultural Machinery:

– Many agricultural machines, including tractors, combine harvesters, and sprayers, utilize hydraulic cylinders for critical operations. Hydraulic cylinders are used to control the movement of attachments, such as front loaders, backhoes, and plows. They enable functions like lifting and lowering implements, adjusting cutting heights, and controlling the positioning of harvesting equipment. Hydraulic cylinders enhance efficiency and productivity in agricultural operations.

3. Material Handling Equipment:

– Hydraulic cylinders are integral components of material handling equipment, such as forklifts, pallet jacks, and cranes. These machines rely on hydraulic cylinders to lift and lower loads, tilt platforms or forks, and control the movement of lifting mechanisms. Hydraulic cylinders provide the necessary strength and precision to handle heavy loads and ensure safe and efficient material handling operations.

4. Industrial Machinery:

– Various industrial machinery and equipment heavily rely on hydraulic cylinders for critical functions. Examples include hydraulic presses, injection molding machines, metal-forming machines, and hydraulic-powered robots. Hydraulic cylinders enable precise control of force and movement in these applications, allowing for accurate shaping, pressing, and assembly processes.

5. Mining Equipment:

– Hydraulic cylinders are extensively used in mining machinery and equipment. Underground mining machines, such as continuous miners and longwall shearers, utilize hydraulic cylinders for cutting, shearing, and roof support operations. Surface mining equipment, including hydraulic shovels, draglines, and haul trucks, rely on hydraulic cylinders for tasks like bucket movement, boom extension, and vehicle suspension.

6. Automotive Industry:

– The automotive industry extensively utilizes hydraulic cylinders in various applications. Hydraulic cylinders are employed in vehicle suspension systems, power steering systems, convertible tops, and hydraulic brake systems. They enable smooth and controlled movement, precise steering, and efficient braking in automobiles.

7. Aerospace and Aviation:

– Hydraulic cylinders are utilized in aerospace and aviation applications, such as aircraft landing gear systems, wing flaps, and cargo handling equipment. Hydraulic cylinders provide the necessary force and control for extending and retracting landing gear, adjusting wing flaps, and operating cargo doors, ensuring safe and reliable aircraft operations.

8. Marine and Offshore Industry:

– Hydraulic cylinders are essential components in marine and offshore equipment, including ship cranes, winches, and hydraulic-powered anchor systems. They enable lifting, lowering, and positioning of heavy loads, as well as the control of various marine equipment.

These are just a few examples of machinery and industries that heavily rely on hydraulic cylinders. The versatility, power, and precise control offered by hydraulic cylinders make them indispensable in a wide range of applications, where controlled linear motion and force are essential.

editor by Dream 2024-04-30

China Hot selling China Made Low Price Telescopic Hydraulic Custom RAM for Refuse Collection Vehicles custom hydraulic cylinders

Product Description

China made low price telescopic hydraulic custom ram for refuse collection vehicles

- Product information

- Specification

|

Material

|

Tube – Cold Drawn / Honed Tubing Piston Rod – Chromed, ground & polished 45#steel Rod Seals – Polyurethane U-Cap End Caps – Steel, threaded fixed Wear Ring – Nylon Backup Washer Mounts – Trunnion with angular Swivels |

|

Application

|

Agriculture, Concrete & Asphalt, Cranes, Fire & Rescue,Forestry & Logging,Mining & Rock Crushing,Oil & Gas,Snow & Ice Control,Waste Management and Material Recycling Industry , Engineering Equipment, Special Vehicle, Fitness equipment

|

|

Feature |

1.High quality with a reasonable price 2.ISO9001-2008 3.Customized specification are accepted |

|

Payment |

T/T;L/C,WESTERN UNION |

|

Port |

HangZhou/ZheJiang , China |

|

Quotation |

According to the specific request |

|

MOQ |

According to the product |

|

Packaging

|

metal case;plywood case;carton or as requirement |

|

Delivery time |

30days upon receipt of 30% deposit; or upon receipt of relevant L/C; |

- About us

We specialize in this line for more than 20 years and trader with main products as follows: hydraulic cylinders, hydraulic power units, hydraulic manifolds-blocks, hydraulic flanges,pneumatic cylinders and custom-made components and parts, like industrial valves.

Our sales markets have covered North America, Europe, Australia, Japan and ect.

- Working Process

- Packaging & shipping

- FAQ

Q1: Do you accept OEM manufacturing?

A1: Yes! We do accept OEM manufacturing. We will quote you the exact price and make the exact cylinder according to your specification and drawing.

Q2: Can we design our own package or print our own logo?

A2: Yes! Package and logo will be made acording to your requirements.

Q3: Could we get small quantity samples?

A3: Yes! We understand the quality test is important and we are glad to make the sample for you. The MOQ is 1pcs.

Q4: How long is the production time?

A4: Generally the production time is 30 days.

Q5: What is the warranty?

A5: 12 months against B/L date.

Contact me, any comments will be appreciated.

Ellen Wang

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 159/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

The Basics of Hydraulic Cylinders

Basically a hydraulic cylinder is a mechanical actuator which can be used for giving unidirectional force. It has various applications in civil engineering, construction equipment, manufacturing machinery and elevators.

Single acting vs double acting

Generally speaking, single acting and double acting hydraulic cylinders function differently. Double acting cylinders have two ports, and apply pressure on both sides of the piston. Single acting cylinders have a single port.

Hydraulic cylinders are used in a wide variety of applications, including manufacturing machinery, construction equipment, and civil engineering. Their main use is on mobile equipment such as graders and excavators. They are also used in reciprocating engines and hydraulic rams.

Single acting hydraulic cylinders are generally smaller and more compact than double acting cylinders. They are also simpler in design and require less maintenance. They are suitable for heavy-duty applications such as lifting and ejecting parts from conveyor belts. They are also cheaper to manufacture. However, they have a limited range of motion, and have limited power and control.

Double acting cylinders, on the other hand, offer more flexibility, faster operation, and greater power. They are also better suited for applications that require precise retraction control. They are more durable than single acting cylinders, and are commonly used in heavy industrial applications. They also have more design variation.

In order to determine whether you need a single acting or double acting cylinder, you should first consider your power requirements. Single acting cylinders are better suited for applications that require only a small amount of force, but require several stroke cycles. Double acting cylinders are suited for applications that require more force, but require a higher number of stroke cycles.

Single acting cylinders are more economical to buy and install, but they are not as compact as double acting cylinders. They are also not as reliable as double acting cylinders. In addition, they may require a second port to convert a single acting cylinder into a double acting cylinder.

Piston rod

During the design phase of a hydraulic cylinder, many factors must be considered. These include the function, materials, and the environment in which the cylinder will be used.

The most important part of the hydraulic cylinder is the rod. It performs the reciprocating motion and is attached to the piston by threads. It also acts as the structural component of the cylinder.

The rod itself is made from chrome plated steel and is usually 10 to 30 millimeters thick. It is plated with a thick layer of chromium to increase wear resistance and temperature resistance. The rod also has an o-ring on its end to prevent the high-pressure oil from escaping.

The rod is connected to the piston by a backup ring and two o-rings. The o-rings keep the rod centered in the barrel, while the backup rings protect the o-rings from escaping when high pressures are applied from the opposite side.

The most important feature of the piston rod is its buckling resistance. The rod may be solid, hollow, or heat-treated. The buckling resistance of a rod depends on its length and its diameter. The longer the rod, the less force it needs to withstand a buckling load.

Another important feature of the rod is its slenderness ratio. This ratio is calculated by measuring the effective length of the rod. This ratio is usually calculated by using Euler’s theory.

The cylinder head is another important part of the hydraulic cylinder. The head has ports that allow hydraulic fluid to enter and exit the barrel. It also has a check valve to prevent oil from leaking out.

The cylinder head also serves as a mechanical stop for the piston. It has two seals: a gland seal and an internal seal. The gland seal prevents the high-pressure oil from escaping, while the internal seal ensures that the o-ring seal is in place.

Welded body vs flanged connection

Generally, there are two kinds of connections for hydraulic cylinders: flanged and welded body. The flange connection is usually used in applications where there is exceptionally high pressure. A welded body connection can be used in places where space is limited. It also improves the overall appearance of the equipment.

Hydraulic cylinders are used in a variety of applications, including earth moving equipment, metal sheet shearing machines, and hydraulic bending machines. They are also used in particle board making hot press machines. The majority of hydraulic cylinders are made from alloy steel combinations.

These materials are prone to rusting, especially when used in humid environments. They may also require coating to prevent corrosion. Hydraulic cylinders can be made of stainless steel or alloy steel. Stainless steel is usually used in marine environments because of its corrosion resistance.

Hydraulic cylinders come in a variety of designs, including single acting cylinders, double acting cylinders, and telescopic cylinders. Single acting cylinders are designed for pushing motion, while double acting cylinders are designed for a linear motion. They are available with threaded, socket weld, or welded body connections.

The rod of a hydraulic cylinder operates outside of the barrel, pushing hydraulic fluid inside the barrel. The piston rod needs to be protected from wear, and the outer diameter of the piston rod is usually coated with a corrosion-resistant surface.

Hydraulic cylinders are typically made of carbon steel, stainless steel, or alloy steel. There are a variety of coatings available, including chrome (nickel) plating, laser cladding, and hard chrome plating.

The most important seal in hydraulic cylinders is the rod seal. This seal needs to be slow to wear, and it needs to be able to resist multiple rod movements. It must also be able to remove contaminants from the hydraulic fluid.

Pneumatic actuators vs hydraulic actuators

Compared to hydraulic actuators, pneumatic actuators are cheaper and less powerful. However, they offer higher uptime and increased productivity. This makes them a good choice for light to medium duty applications.

Pneumatic actuators use air pressure instead of hydraulic fluid, and they provide a reliable motion that is ideal for window manufacturing. They have a simple design that reduces maintenance. They can be used in various applications, including food production, automotive manufacturing, and industrial machinery.

Hydraulic actuators are better suited for heavy duty applications. They can handle higher pressures and generate more force than pneumatic actuators. But they can leak fluid, which can invite contamination. They can also be noisy, without the use of noise-reducing equipment.

Hydraulics also require pumps and reservoirs for fluid. There are also valves, pistons, and companion parts to maintain the system. It is important to check for leaks and maintain the system.

Hydraulic actuators are used in heavy construction equipment, nail guns, precision drills, and moving machinery. Hydraulic cylinders provide 25 times the force of pneumatic cylinders.

Hydraulic systems can be a good choice for heavy duty applications, but they can also cause more problems. For example, the pressures can be very high, and they can leak fluid. Hydraulics require regular maintenance, which increases the overall cost of ownership. They can also lead to contamination of the internal working parts of the system.

The biggest advantage of hydraulic actuators is their ability to create and hold torque. It’s important to monitor the temperature of the fluid to avoid leaks. If there is a leak, the fluid can be contaminated and damage internal working parts.

Hydraulic actuators require more care and maintenance, and they may be more expensive than pneumatic actuators. The cost of maintenance may also affect the lifespan of the device.

Cushioned vs non-cushioned cylinders

Depending on the application, cushioned hydraulic cylinders can be used as a cost-effective and useful tool for reducing shock loads. The cushioning can take a variety of forms, from external shock absorbers to internal cushions.

Cushioning is the process of decelerating the cylinder rod near the end of its stroke. This reduces vibration and reduces stresses on components. However, too much cushioning can reduce the efficiency of the machine, especially for pneumatic cylinders.

The cushioning effect is achieved by restricting the flow of hydraulic fluid exiting the cylinder port. This is achieved through a small orifice that allows the flow to be controlled. The smaller the orifice, the more controllable the cushioning effect.

A typical example is a double-acting cylinder with double-sided cushioning. The cylinder is constructed with a check valve oriented from port A to port B. This valve is set to operate from a minimum of 10 millimeters before the end of the stroke.

The cushioning effect can be regulated externally with an adjustable screw. In order to determine the amount of cushioning required, it is important to consider factors such as cylinder size, stroke, and application.

In addition to being able to control the flow of hydraulic fluid, the cushioning effect can also be used to protect the entire system. It can be used to restrict the exiting flow of hydraulic fluid so that the incoming flow can reach maximum pressure.

Cushioning can be used in conjunction with other methods to reduce shock loads. For example, a fast start-up method can reduce the impact force of the cylinder. A cushion design can also increase the rate at which fluid returns to the cylinder when it leaves the cushion.

editor by Dream 2024-04-29

China Professional American Starcyl Heavy-Duty Hydraulic Cylinder St6df1-3.25X22.22X1.38 Standard Rod Cylinder with high quality

Product Description

Q1: How can contact sales?

A1: Contact with us in TraderManager, or send email to us.

Q2: How to make payment?

A2: Paypal, Western Union, Money Gram or T/T transfer

Q3: How long does it take to process orders?

A3:It usually takes 10-14 business days to process most orders for no stock, if stock available, only take 2- 3 business days.

Q4: What is the packing method?

A4: For small piece, we use carton box; for big piece, we use exporting grade plywood case.

Q5: How to ship?

A5: Sea freight, Air freight or International express(DHL, FEDEX,UPS…) all are available.

Q6: What is the warranty

A6: 12 months against B/L date

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 120/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle the challenges of precise positioning and control?

Hydraulic cylinders are designed to handle the challenges of precise positioning and control with a combination of engineering principles and advanced control systems. These challenges often arise in applications where accurate and controlled movements are required, such as in industrial automation, construction, and material handling. Here’s a detailed explanation of how hydraulic cylinders overcome these challenges:

1. Fluid Power Control:

– Hydraulic cylinders utilize fluid power control to achieve precise positioning and control. The hydraulic system consists of a hydraulic pump, control valves, and hydraulic fluid. By regulating the flow of hydraulic fluid into and out of the cylinder, operators can control the speed, direction, and force exerted by the cylinder. The fluid power control allows for smooth and accurate movements, enabling precise positioning of the hydraulic cylinder and the attached load.

2. Control Valves: